Water Quality Montoring: Feeding a Nation, One Sensor at a Time

Singapore’s bold “30 by 30” initiative aims to produce 30% of the nation’s nutritional needs locally by 2030. Among those leading this transformation is The Fish Farmer, a sustainable aquaculture company operating coastal farms in Lim Chu Kang and Changi. But scaling production in tropical waters comes with risks, especially when environmental conditions and human labour limitations threaten yields.

To tackle these challenges, The Fish Farmer collaborated with IOT-ezy to implement LoRa-enabled water quality sensors along with a centralized alert and monitoring system. This initiative positioned the company as an early adopter of IoT and AI in local aquaculture, leading to tangible improvements in operational efficiency, sustainability, and environmental responsiveness.

Challenge #1: Oxygen Levels in Open Waters

Fish farms using open sea cages face a serious and ongoing issue: fluctuating dissolved oxygen (DO) levels. During certain seasons, low DO can cause large-scale fish deaths within just a few hours. Traditionally, workers relied on handheld meters to check oxygen levels manually, a reactive and labour-intensive process. Since DO levels are invisible to the naked eye, the use of continuous water quality sensors is especially valuable, providing real-time data both day and night to support faster, more informed decision-making.

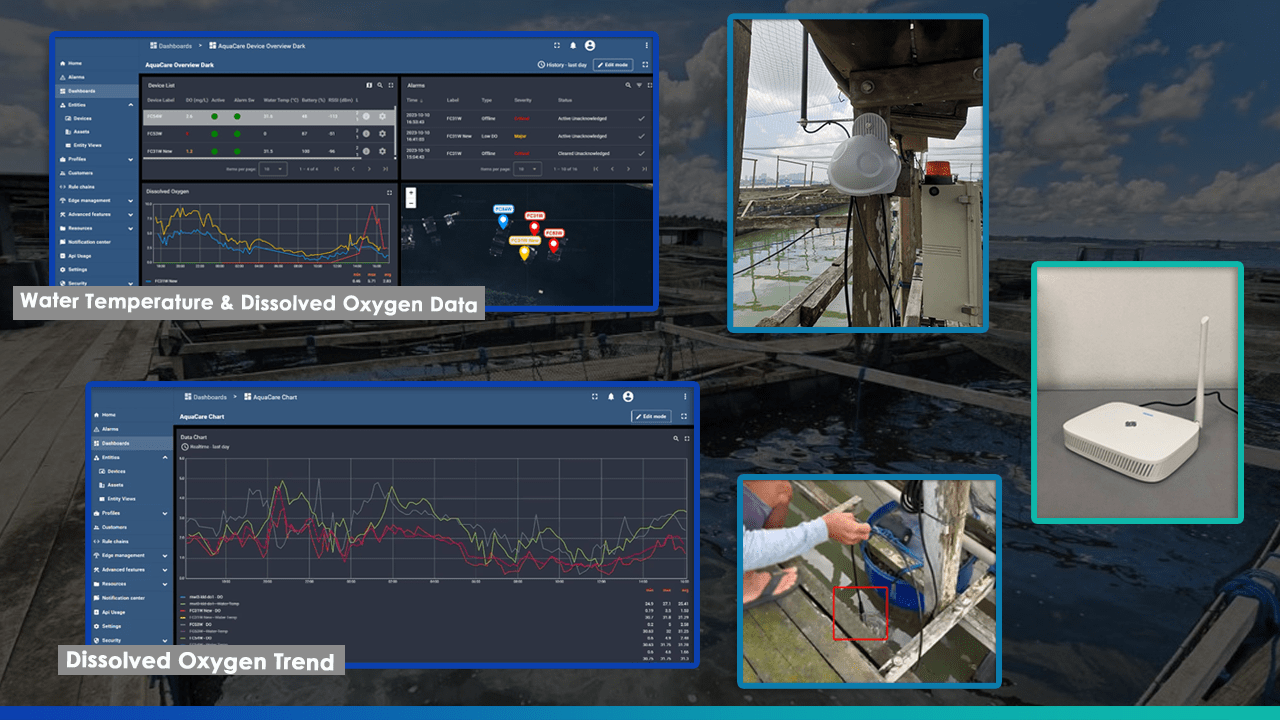

IoT-Driven Monitoring in Real Time

The farm installed rugged, LoRa-based IoT water quality sensors capable of continuously monitoring DO and temperature in each fish pen. These sensors transmit data wirelessly via a central gateway to a cloud platform, accessible on mobile and desktop dashboards.

Alerts are triggered when DO drops below safe thresholds, allowing staff to act quickly and trigger aeration systems or adjusting feeding schedules. The system also logs historical data, giving the farm insight into long-term patterns and environmental triggers.

Challenge #2: Manual Fish Counting and Cold Storage Losses

Another operational pain point was fish counting and sizing this is critical for both inventory tracking and sales forecasting. Staff previously relied on physical sampling and estimation, which was labour-intensive and prone to inaccuracy and it was also time consuming to do this mundane task.

At the same time, cold storage units used to preserve harvested fish were vulnerable to unnoticed temperature spikes, risking spoilage and revenue loss.

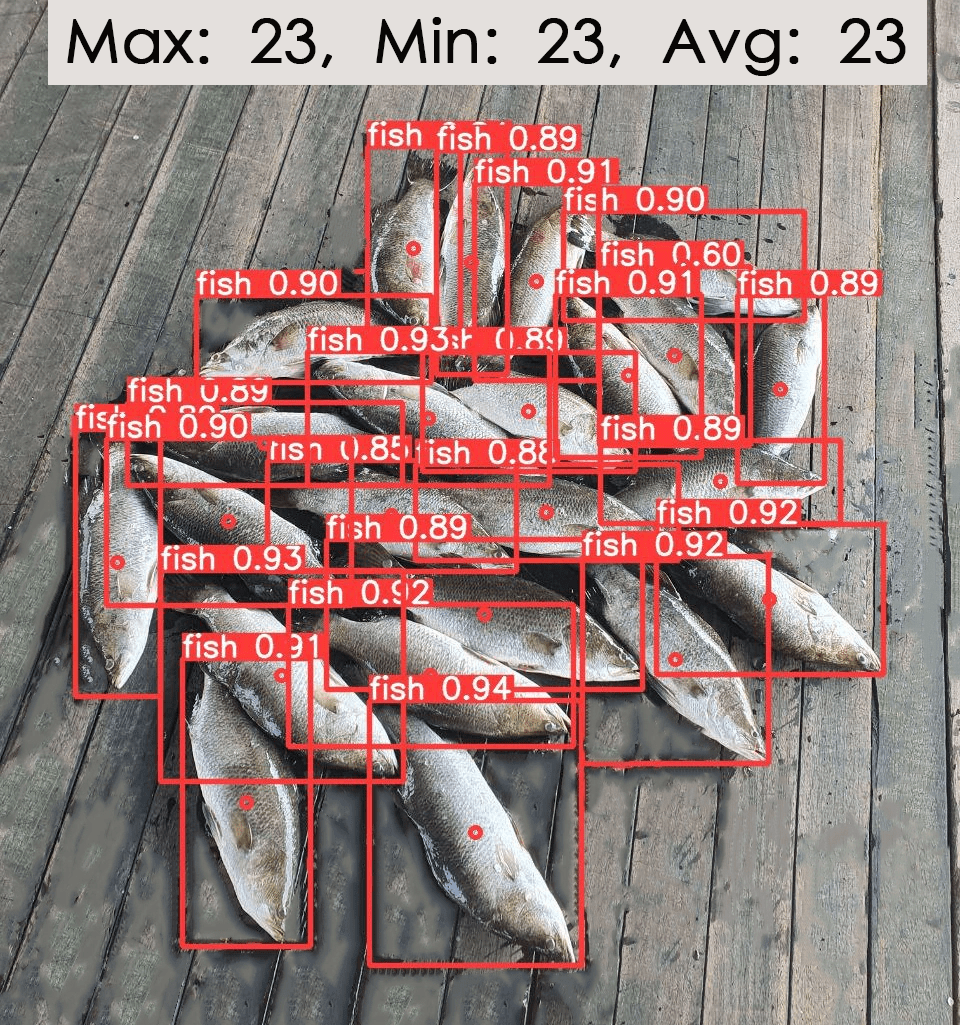

AI Vision and Cold Room Monitoring

The farm implemented AI-driven video analytics systems capable of detecting and counting fish from underwater footage. These systems estimate fish length and weight automatically, reducing manual labour while improving precision.

Additionally, wireless temperature and humidity sensors were installed in cold rooms. These generate alerts if temperature thresholds are exceeded; enabling rapid intervention before any spoilage occurs.

Results: More Resilient and Data-Driven Operations

Since implementation, the farm has reported:

- A significant drop in fish loss due to early DO detection

- Better feed conversion ratios and reduced overfeeding

- Time savings in fish inventory and reporting tasks

- Cold-room failures prevented thanks to real-time temperature alerts

The combination of sensor data and AI tools has empowered the team to operate proactively rather than reactively which enhances both sustainability and profitability.

Beyond the Farm: A Model for Urban Aquaculture

This project not only helps The Fish Farmer scale up responsibly, but also serves as a replicable model for other urban and coastal farms in Southeast Asia. With climate variability and labour shortages increasing, smart aquaculture systems could be key to meeting food security goals across the region.